What precautions do you need to know for lithium batteries in series vs parallel?

With the maturity and commercial application of lithium battery technology, limited by the voltage and capacity of the single battery, in order to meet the high voltage and large capacity requirements of electrical equipment, energy storage systems & power equipment types, engineers will The parameter specifications of the group require series, parallel or connecting cells in series and parallel circuit design.

On the other hand, lead-acid batteries have been widely used. Lead-acid batteries are also connected by cells in battery series vs parallel on the same principle. However, due to the high chemical stability of its materials, lead-acid batteries do not need a protective board BMS to manage, control, and protect.

The batteries in series vs parallel connection of lead-acid batteries is very simple and convenient. Users only need to use compliant aluminum bars or copper wires to connect the positive and negative poles of lead-acid batteries. This method has been familiar to consumers.

However, lithium batteries, cannot connect in series & parallel and use. Although the performance of Li-ion batteries is very strong, the reason is that there will inevitably be inconsistencies in the manufacturing process of Li-ion cells (lead-acid batteries do not need much attention due to their material properties), inconsistencies (extremely tight intervals Standard), will be gradually enlarged with the increase of cycle use and cycle life.

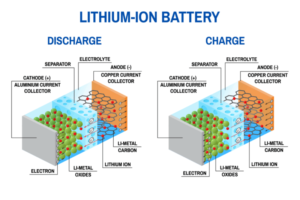

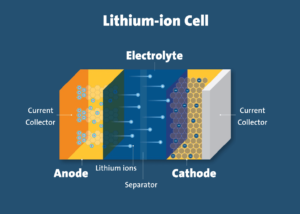

The main parameters of lithium-ion cells, such as internal resistance, current, voltage, and other parameters will be different in different states of charge, and these main parameters determine the consistency of lithium-ion cells.

Under the barrel effect, the strong lithium-ion battery will become stronger, and the weaker will become weaker until the entire lithium-ion battery system accelerates decay, failure, decommissioning, or thermal runaway. The series and parallel modes of lithium-ion cells have a huge impact on the performance of the battery system.

In the process of using lead-acid batteries, consumers have formed a default awareness of the series-parallel use of batteries, but whether lithium-ion batteries can be used after series-parallel connection depends on the performance and solution design of the battery’s BMS system.

Whether to support series and parallel use, you need to confirm with your supplier or brand seller to operate, otherwise, the battery cells or BMS will be damaged quickly during use.

Are you curious about the reasons for supporting and not supporting to wire series vs parallel by lithium-ion batteries?

Despite the huge advantages of lithium-ion cells, the rise and popularity of electric vehicles have proven their superior performance.

because of the high energy density of lithium-ion cells and the activity of materials, various factors can cause and lead to the performance of lithium-ion batteries being damaged or failing.

The charging and discharging process of the lithium-ion cells inside the battery must be managed, controlled, and protected by the BMS system in order to maximize its performance and cycle life advantages.

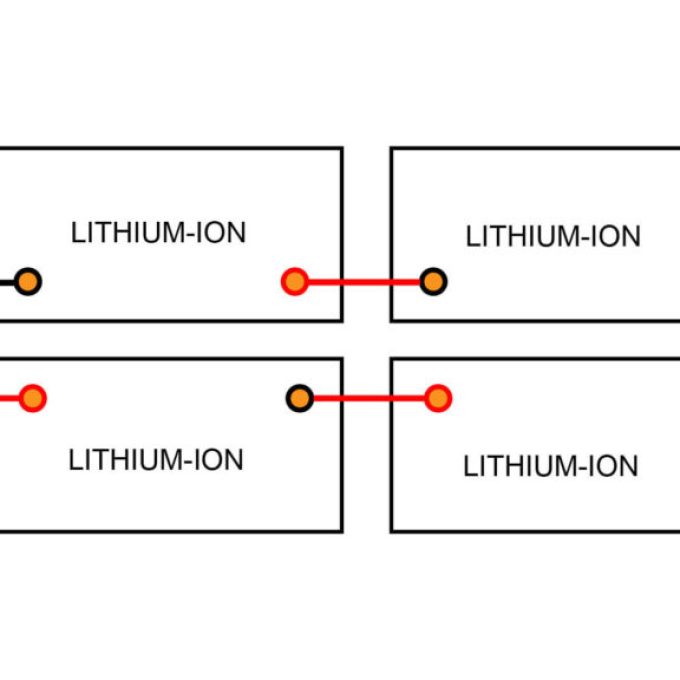

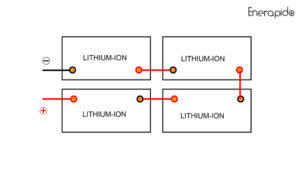

At present, there are two types of series vs parallel circuit solutions for lithium batteries, communication-type series-parallel solutions, and physical series-parallel solutions.

The communication type series-parallel connection is the synchronization of charging and discharging parameters realized by the communication management of the battery’s BMS system. This type of series-parallel technology is used in home energy storage and commercial energy storage modules.

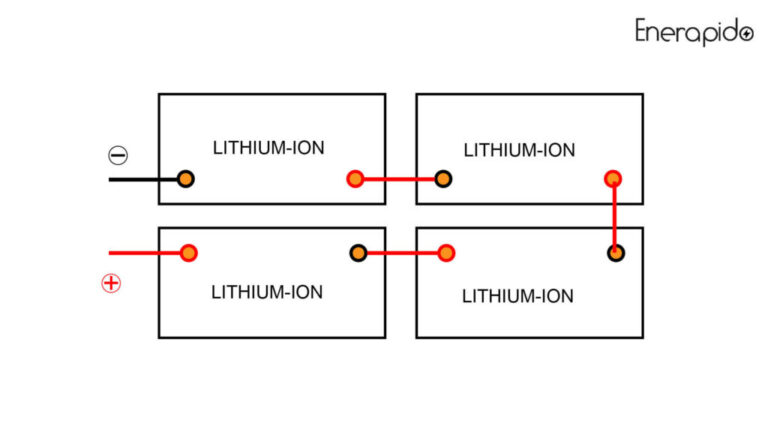

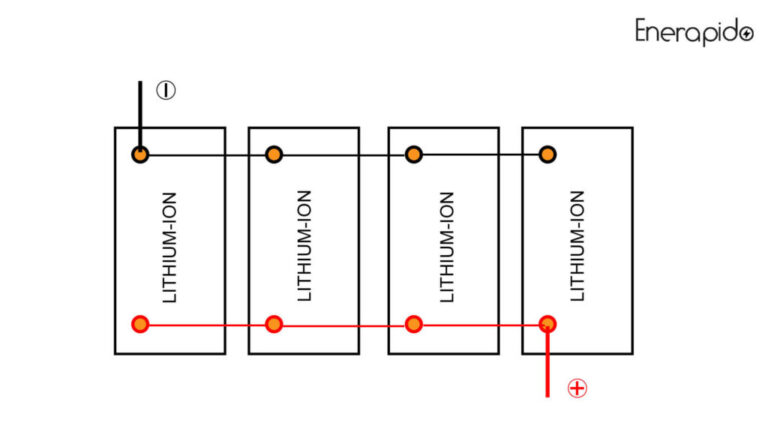

We mainly explain the physical series-parallel connection of lithium batteries. The simple explanation is whether the withstand voltage and overcurrent value of the battery’s BMS system can withstand the current and voltage values during charging and discharging after the battery is connected in series and parallel.

Use of batteries in series

- The requirements for the protection board are more stringent, and the consistency of the BMS of different batteries is more stringent.

- The maximum number of strings connected in series determines the maximum withstand voltage of the MOS. During the charging and discharging process, if the BMS of a group of batteries is automatically protected, the voltage will break down the MOS in the BMS system, and the battery will fail.

- Each BMS of the battery in series must be able to withstand the same current and voltage and has higher requirements for the withstand voltage and quality of the MOS. In addition, the series connection mode & charging and discharging type of the BMS must be the same port type.

Use of batteries in Parallel

- Higher requirement for battery consistency. For example, if two battery packs are used in parallel, their voltages are the same, but the internals are different, so the current provided by the batteries is inconsistent. Similarly, the voltages are different, the internal resistances are the same, and the currents provided are also inconsistent. If they are not the same, the difference in the current provided is even greater.

- Since both the battery and the BMS have internal resistance, there is also a high requirement for the consistency of the internal resistance of the BMS.

In the current loop, if the overcurrent protection value of the BMS is the same, but the discharge current is different, the BMS of one battery will enter self-protection, and the other battery can discharge normally, but after the overcurrent is over, all the current will be withstood by these batteries. Prolonged use will cause the battery to decay faster. - During discharge, if a single battery reaches the protection value, the total discharge current will be distributed to other batteries. During long-term use, the decay of the battery will accelerate, resulting in worse consistency.

Therefore, Precautions for the use of lithium batteries in series vs parallel, in addition to the high requirements for the consistency of lithium batteries, the performance and consistency of BMS also have high requirements.

If the consistency of the battery pack is not good, its cycle life will be greatly reduced. It will increase the workload of the BMS and accelerate the aging or damage of the BMS.

In usage scenarios and equipment applications, there are various requirements for the function of batteries in series vs parallel. Menttop has launched series vs parallel battery solutions for energy storage and power batteries.